Air Coils

Quality – Integrity – Reliability

PMT supplies replacement air coils for HVAC applications. These coils can be designed based on your existing design documentation, or PMT can dispatch our design team to your site to reverse engineer your existing coils.

For applications where water chemistry is problematic, PMT can perform an engineering evaluation to compare a new coil to your existing one, and then propose new coils made from alternate materials.

PMT can perform full thermal performance testing on the coils to validate heat transfer and confirm the design meets your specifications. Installation services are also available.

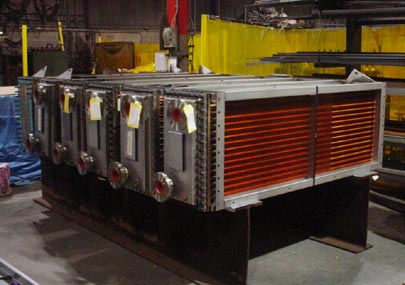

Containment Fan Coils

PMT manufactured 30 containment fan coils for the Point Beach Plant. The original coils were in leaking due to age. The utility replaced all installed coils. These coils have a removable water box cover for cleaning. The original coils did not have water boxes. Call PMT today for specific information regarding coil services.

The water box cover is tach welded together on a jig.

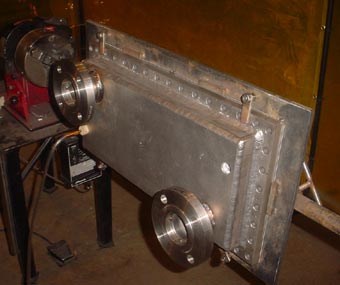

Cover ready for heat treating and machining.

The water box cover is back in the weld shop to have final welding completed.

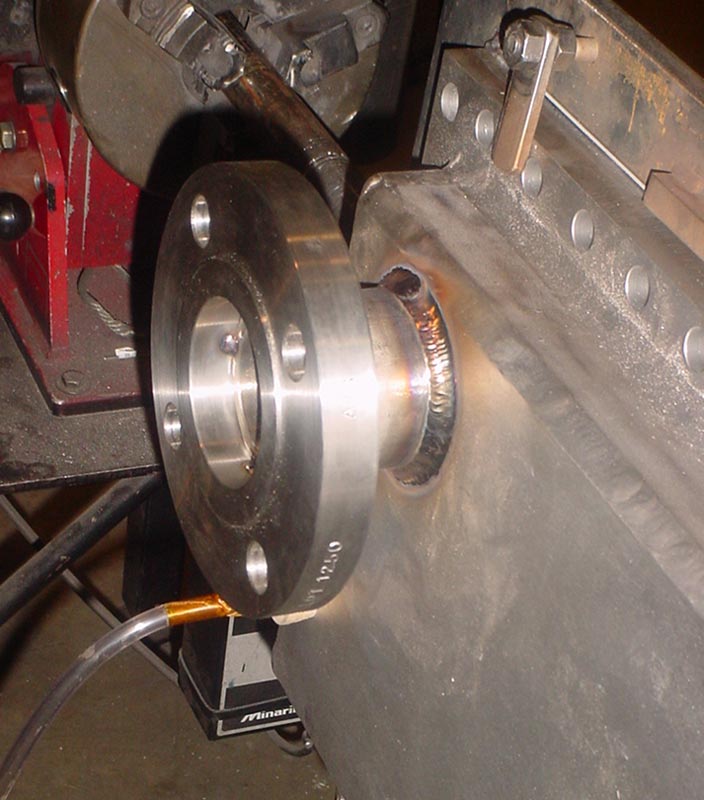

Cover pass welds being completed.

Flange tack welded on water box cover. Note the cover was heat treated, machined including flange face, bolt holes and vent holes. After heat treating but before machining, the cover was bead blasted to remove all heat treating residue.

Back side of water box cover and tube sheet showing two pass operation.

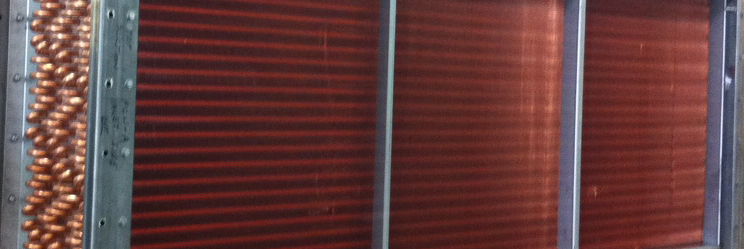

Finned coil with tube sheet rolled.

Coil back side.

Assembled coils ready for pressure testing. Then to be boxed up and sent to the customer for installation.

Give Us A Call Today!

Visits: 728